IESE Insight

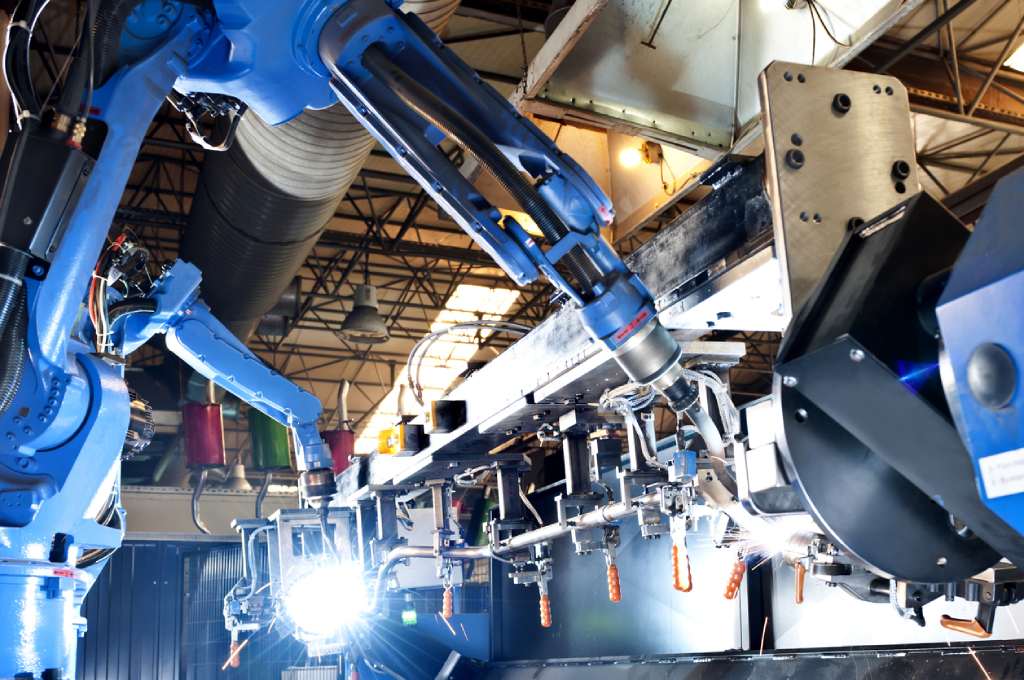

Connected Robots: Industry 4.0, Automation, and Why We Need to Let the Robots Communicate

Robotics is a game-changer, but what does this mean in practice, from staffing to performance metrics? Stefan Lampa, CEO of Kuka Robotics, on the future.

We live in volatile, uncertain, complex and ambiguous (VUCA) times, and manufacturing is facing an era of disruption.

The first, second and third industrial revolutions brought changes as disparate as the steam engine, electrically powered factories, computerization and lean management. Now, Industry 4.0 is ushering in new developments, from Big Data applications to human-machine interaction.

At the 32nd IESE AUTO Industry Meeting in November 2017, Professor Marc Sachon sat down with Stefan Lampa, CEO of Kuka Robotics, to discuss what robots do in manufacturing today — and what they could do if we gave them the chance. Also on the agenda: changing talent profiles in the manufacturing sector and what different regions need to do to stay competitive.

Marc Sachon- Kuka is a high-tech expert within the robot industry. Your task has been to internationalize and grow the business outside Germany. Are there insights that you can share about the profile of people that are working at Kuka? Has the profile changed in the context of Industry 4.0?

Stefan Lampa- Traditionally, people working in factories learned on the job, and often stayed their whole lives. Those days are over. In the manufacturing industry, many manual jobs are being replaced with robotics and automation, and more advanced technical skills are required. Finding solutions for new product designs requires quite a bit of creativity. I think this is a generalized change happening in society.

In the future, our greatest demand will be for people with social skills. It's about communication. We'll need to pull different skills together, and not just at management level: this need for communication will be throughout the value chain.

At Kuka, we are hiring new talent and retraining workers in order to bring curiosity and entrepreneurship into the organization and to find solutions to new challenges. As always, some people are very excited about it, and other people are less excited.

MS- On a technological level, what can your robots do today?

SL- Today, the only thing that hinders robots is our own creativity and obviously the customers' desires or our opportunities to convince them. We have robots that can carry more than a ton. We have robots that can move so fast that you can't see them, and we also have robots that are so highly sensitive they respond to touch. Those things make us extremely proud, because many of them were pioneered at Kuka, such as sensors in the robots.

MS- You've spoken before about connecting robots so that they can exchange experiences.

SL- If you look at today's manufacturing giants, many have the same factory doing the same thing in eight different countries, and all with different results. Connecting the robots, or robot processes, can change that. This can clearly help the customer. And with artificial intelligence, we can get ideas from algorithms. For example, we'll see a red flag if there's too big a difference in performances where there shouldn't be. It's an exciting time, and now it's up to our customer base to let us see more; to open up to connectivity and let us take a deeper look at what they are doing.

MS- If we look at car factories, for example, there are robots everywhere. Not just in the body shop but in the paint shop and in final assembly. To what degree could a robot gather data throughout the factory, especially robots with sensors, data which might then be valuable to the company operating the factory by taking it in the direction of Industry 4.0?

SL- Many of the errors or imperfections in products are seen late in the production chain, although they occurred much earlier. It might even be that material coming into the production line wasn't good enough and that discovery is made very late, which can be very, very expensive, especially for automotive products. Sometimes these products even get as far as the customer.

But by connecting these processes to a web-based platform, we can track a problem back to its root cause, catch it early, bring down costs and improve productivity and customer experiences. Connected robots can have a learning cycle and automatically improve what they are doing.

MS- Let's talk about markets. In the past the big markets for robotics have been North America, Europe and, of course, Japan. Lately China has become the largest market for robots by far. How do you see China developing, not just as a robotics market, but also as a competitor?

SL- As a competitive landscape, China is very interesting. There are hundreds of robot companies, and many of those are growing because the Chinese Government is strongly promoting the "Made in China 2025" manufacturing program. But since there are so many competitors, the market has become very fragmented and few companies are really maturing. At this time, the Chinese companies are very much covering their entry segment for robotics and that's something we leave to them. I expect, out of a hundred Chinese companies that exist today, 20 are fairly big already, and maybe we'll see one or two of them develop into global players in 10 years. Growth will continue in the Chinese market. I wouldn't be surprised to see 20 or 30 percent growth rates every year going forward.

MS- But that surely cannot be driven by the automotive industry alone?

SL- No, everything is getting automated. Today in China almost all manufacturing companies want to automate. They know that it's the end of cheap labor. If manufacturers want to stay alive, they know they need robots and they are really getting on it a lot faster than the rest of the world.

MS- How do you see Europe as a market for robotics?

SL- Europe is very important, as always. Germany is still number four in the world. It will soon be number five, after China, the United States, Japan and Korea. But in any case, the European manufacturing industry really needs to speed up. SMEs in Europe need to do a lot more and I think they require some government support to help them automate. And obviously, we in the robotic industry need to make automation more accessible to them. But if they're going to stay and be competitive, they have an opportunity with the current move to reshoring. They better take this opportunity — and robots are the way for them to be successful.